Raise3D N2+ 3D Printer Review

Hey it’s Joel, the 3D Printing Nerd! This is the Raise3D N2+ 3d printer, and this video serves as my official review. I’ve been using this printer for quite some time, and I cannot wait to tell you about it. Let’s do this! Are you ready? Go!

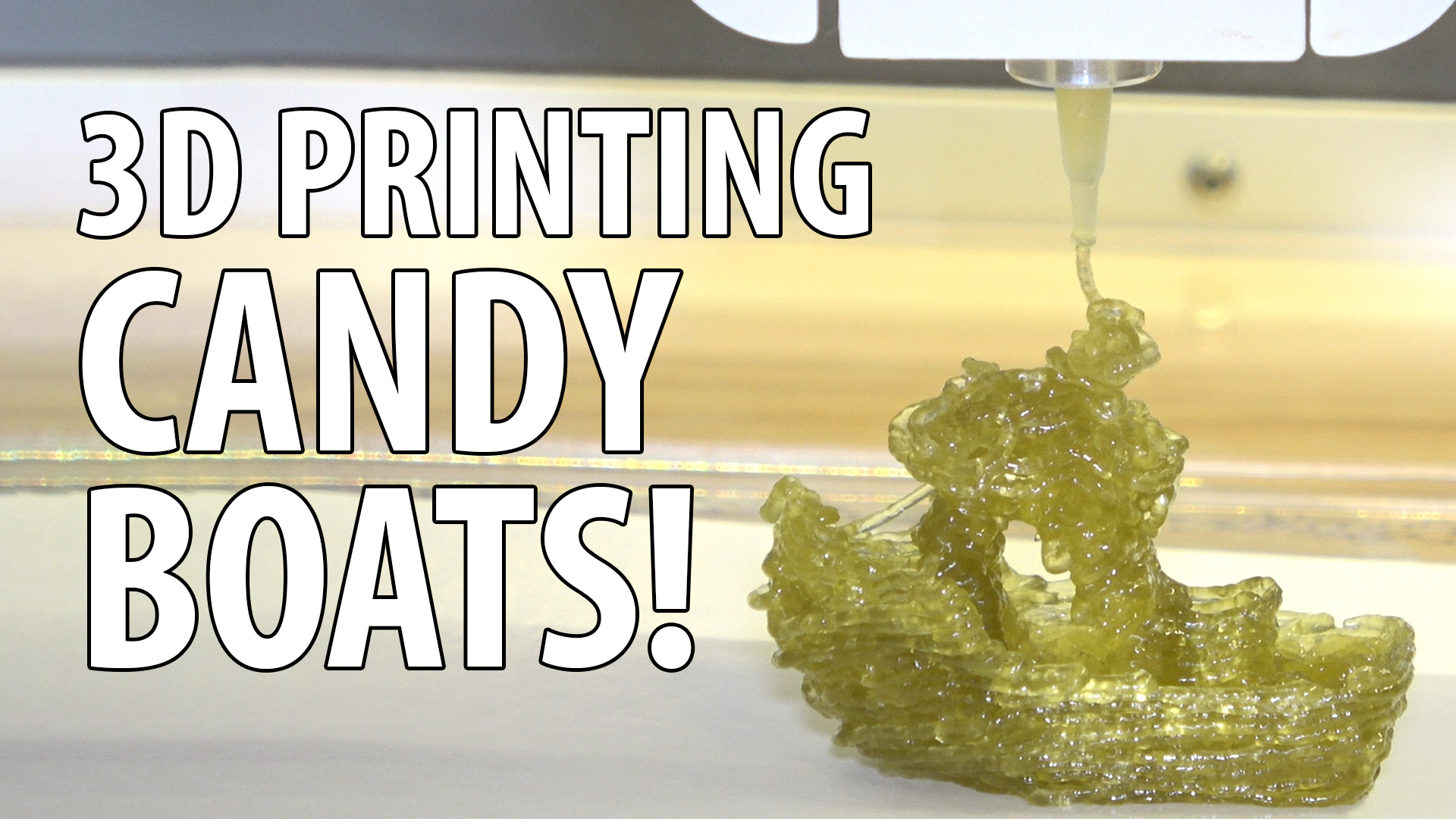

I’ve had the Raise3D N2+ for quite some time now, and I’ve been able to print a number of things with it. I’ve printed small things, I’ve printed big things, I’ve printed dual-color things, I’ve even printed myself a big giant mess.

… Yeah, that sucked.

Overall, even including my unboxing and the ensuing comment storm, I’ve had MUCH more positive experiences with this printer than negative. That’s a good start, however, THAT does not equate a review. With that in mind, let’s get technical.

Solid aluminum frame measuring 24” wide, by 23” deep, by nearly 38” to the ground

12 x 12 x 24 build volume

It’ll go up to 300C on the all metal hot ends

It’ll go up to 110c on the print buildtak on glass print bed

7” full color touch screen

Built-in print resume power failure protection

Beyond the technical specifications, I really like the overall design of this machine. I think the frame is sturdy, the ability to enclose the machine helps with materials that require that, the internal lights provide great illumination of the printer parts, and the large touchscreen interface on the front makes it seem like this printer comes from the future.

Let’s dive a little deeper into the touch interface.

The interface really allows for an easy way to control the printer when compared to using an LCD screen with a twist knob. The screen gives you an info-rich display of the printer and it’s current settings for heat on the nozzles, heat on the bed, and information relating to the current printing model. If you use ideaMaker, their slicing software, you’ll see an image of the model on the screen. You can also dial in various settings, and choose which models to print from the built-in memory, a USB stick, or an sdcard.

ideaMaker also has the ability to send models to the printer using WiFi, and the printer stores this gcode in it’s internal memory. Honestly, for the first few months of using this printer, I NEVER used a USB stick or an sdcard to print – ALL prints were done wirelessly. Plus, ideaMaker replicates the look of the touch screen in a small window on your computer, giving you full remote control of the print job.

At this point, I’d like to go over the stuff I liked, and stuff I didn’t like that much. Let’s get started with the stuff I liked.

I really like the print quality from this machine. I think this printer is able to produce printed model with quality that rival other well reviewed desktop printers, and what makes this printer special, is it’ll produce amazing quality models at an enormous size.

I like the layout and design of the machine, with the touch screen up front, and the filament spools behind a door on the side. The big door up front to access the build area is a nice touch as well. Even the lights in the machine illuminate the build plate in a way that makes it feel more interesting. If the machine is running in a dark room, it just LOOKS cool.

Finally, I like the support I’ve received from the Raise3D company during my time evaluating this printer. The Raise3D team has been incredibly supportive, willing to help out, and always up for answering questions. In fact, I found their presence on Twitter to be quite refreshing. Kudos!

Now, unfortunately, there are a few things I don’t like.

The fan that cools the throat of each extruder is also the same fan that blows air on the print as the printer is printing. This means you cannot adjust fan speeds while printing. The fan is on, always, because it HAS to be. If you want to print with ABS, normally you would set the filament fan to zero for the print, but with this machine, you cannot. Their solution? A small plastic piece you slide over the bottom of the fan shroud to block the air from coming out. I don’t think this is a good solution for a machine of this caliber, I would expect to control the filament fan speed via settings in my slicer.

The printer arrives with the bed leveled at the factory. This worked for most of the build plate, but the edges seemed to be not level. To level the bed, there are no fewer than 13 adjustment points for you to play with. Unfortunately, there is no auto bed leveling. I know, I know, it’s not required, but, I think it would most certainly be helpful, and provide a LOT of benefit to those who would like to print as big as they can. To be fair, 99% of the time, I do not have to adjust the bed level, however, when I do, I find it to be incredibly frustrating.

Lastly, a filament roll on the left spool holder blocks the spool door from closing. In order to close the door, you have to reach in through the front door to move the spool aside while you close the filament door with your other hand. Then, unfortunately, the spool rests on the door. The spool STILL TURNS and their is very, very little friction at this point, but, I think a little more attention to detail right here would have been nice.

In the end, this is a really, really good printer. I think it’s missing a couple key features that would make me officially call this a “great” printer. The print QUALITY is great, and I don’t feel any of the negative points I listed are deal breakers. I sincerely think if you have the budget and the space for this printer, and you pick up this printer, you would be happy with this printer.